Rough on the Outside, Next Level on the Inside

The homebuilt, mid-engine, rear-wheel-drive converted 1989 Honda CRX Si.

From the outside, David Shoger’s 1989 CRX Si is about what you’ve come to expect from a 30-year-old Honda chassis, especially one well known for its vast aftermarket options and a habit of falling into the wrong hands. The mismatched panels and general wear and tear often accompany hatchbacks of this generation but don’t let the “under construction” exterior fool you as this build goes way beyond your typical project.

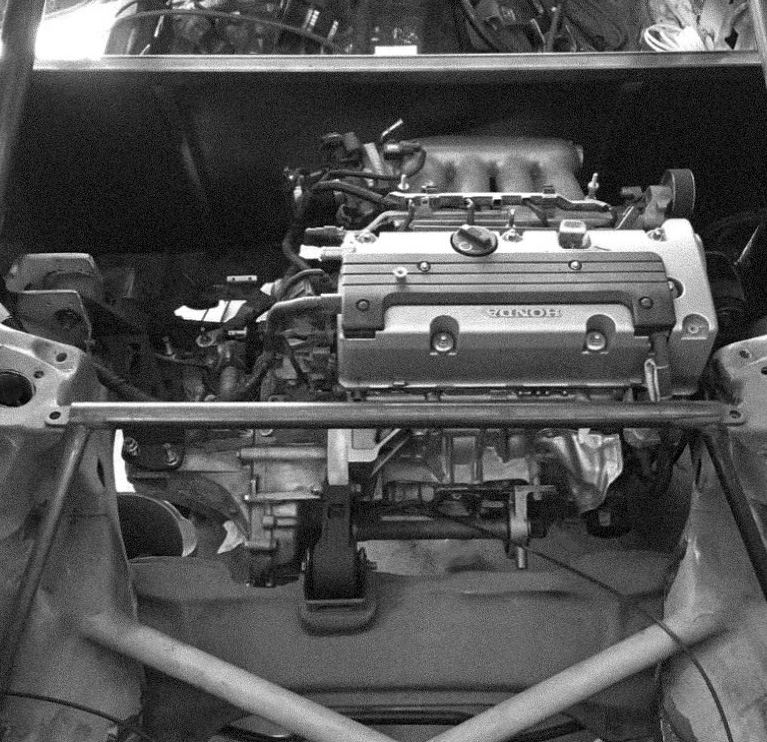

“I’ve had tons of old Hondas over the years, but this one was my forever car,” David tells us. “When normal swaps and bolt-ons no longer interested me, I decided to start cutting.” And cut he did, lopping off chunks of CRX over a period that spanned seven years in his personal game of “on again/off again.” It wasn’t a weight loss program that David applied to the CRX though excess pounds were certainly shed in the process. His vision involved completing a K20 swap, but he had no intentions of mounting it under the car’s hood.

The goal for this build was to create a mid-engine Honda CRX and today, after what David describes as long periods of inactivity, that’s exactly what he’s done. He adds, “The idea for the build was to make it as close to OE spec as possible, as if Honda had designed it this way.” That meant a fully operational gauge cluster, working stereo, functional heater, and windshield wipers. He even went as far as reconstructing the sound deadening mat as he felt Honda would have and reports that ever since the conversion was completed, the car has remained reliable. “I wanted to see it done and I just learned as I went. It really serves no purpose, I just drive it like a normal car,” he adds.

In order to get the K-series to sit in place, some of what you’d see under the hood was moved to the middle of the car. The “bucket” that holds the K-series transmission mount is welded in place, as is the rear subframe’s anchor. Using modified Innovative mounts intended for a standard front-wheel drive swap, the 2.0L sits evenly and leaves plenty of space for future boosted activities. Custom work was of course required to strengthen the area behind the engine to avoid chassis twist and that was addressed with a welded x-bar and additional bracing that connects directly to the shock towers.

The K20 gets a bump in power with a K-Tuned header that leads to custom exhaust piping and Blox mini muffler, and there’s a homemade intake in place. The original fuel tank was removed and replaced with a 12-gallon cell that relies on a Walbro fuel pump and Jegs in-line filter. To coax the chassis new layout and transmission to cooperate, a 2005 Accord shifter was modified and the CRX’s native clutch cable was converted to hydraulic operation via Hush22 conversion kit.

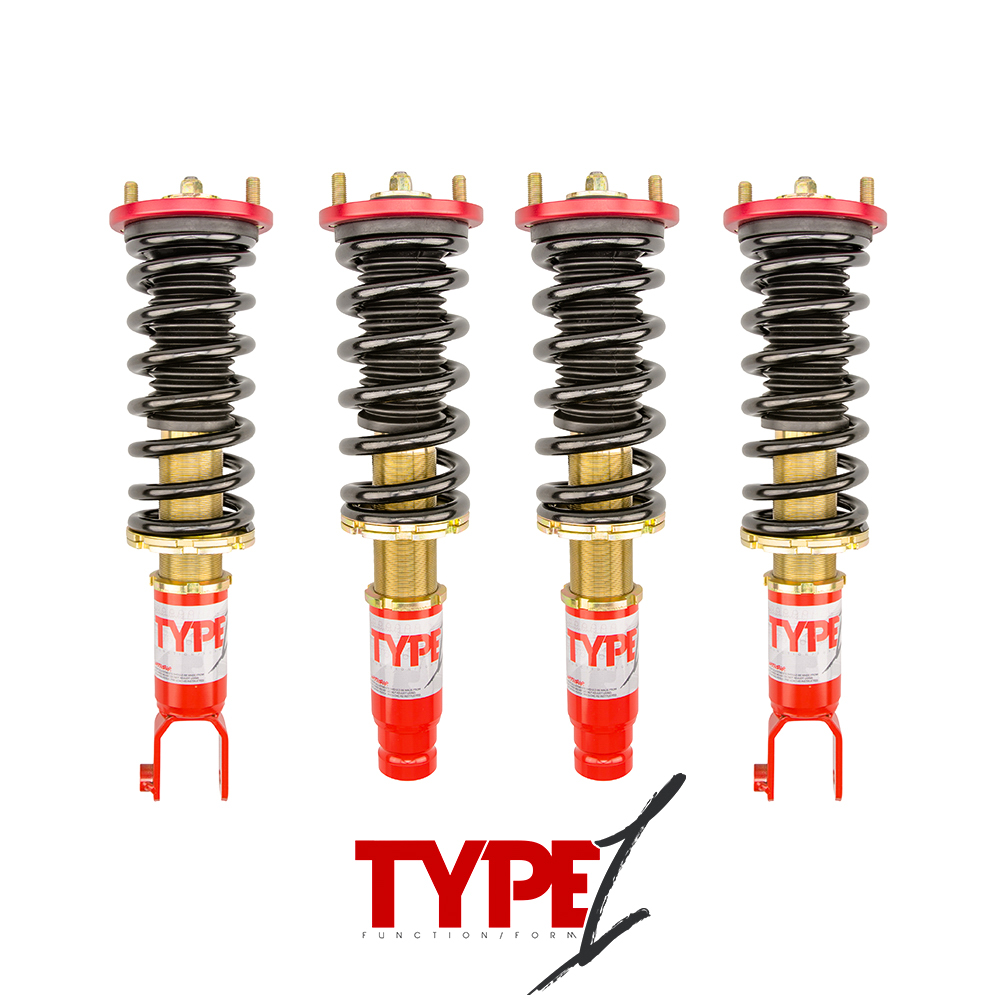

Any lightweight Honda with a bigger, far more powerful engine on board should carry the appropriate suspension in the name of safety and ride comfort. This scenario was even more imperative in David’s case, being that the featherlight CRX had its engine moved closer to the rear and the vehicle’s natural tendency to squat over its back tires under acceleration was multiplied with the reduction of engine bay ballast.

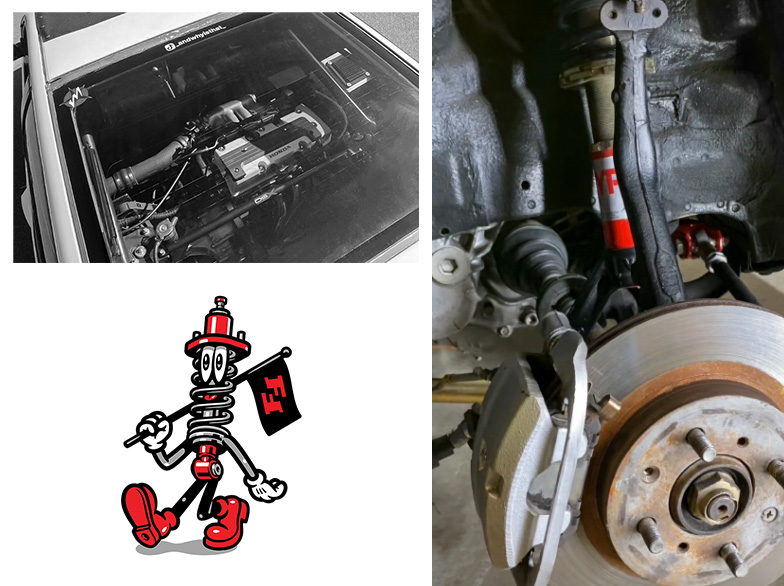

At the same time, this will remain a true streetcar that he uses day in and day out, so stiff competition suspension just didn’t make sense. To that end, he chose Function+Form’s Type 1 full-bodied coilover. With its fixed dampening characteristics already pre-set and matched to less aggressive, more street-friendly spring rates, he gets a smooth ride in any condition, can control the car’s tendency to squat, all the while taking advantage of the mid-engine, RWD layout when the timing’s right.

David Shoger’s CRX Si creation is anything but average, even with its rough around the edge’s outward appearance. The self-made engine and drivetrain conversion is one that very few have attempted, and even less have succeeded in pulling off. For the guy that grew bored with standard go-fast parts and common swaps, this long-term, intermittent project has been his most involved and has resulted in the biggest payoff.

As with any Honda project, it’s never quite over, and David has plenty on his long-term to-do list. He notes, “My intention is to someday repaint it to full yellow, but life comes before cars, so for now it’ll stay multi-color. Other future mods might include new wheels, a small turbo, and a front trunk inlay.” It might be years before all of that happens, but in the meantime, David can be seen enjoying the road from behind the wheel of his one-of-a-kind CRX every chance he gets.

David Shoger’s 1989 Mid Engine Honda CRX Si

Engine Specs K20Z3; Innovative engine mounts; 1980s VW Rabbit radiator; shaved and vented valve cover; Jegs in-line fuel filter; Walbro 190lph fuel pump; RCI 12-gallon fuel cell; JDM ITR throttle body; K-Tuned header, throttle body adapter; MR2 throttle cable; custom intake, air box; Thrush resonator; Blox mini race muffler; 2.25-in. exhaust; Hondata

Transmission & Drivetrain 6-speed trans; 2005 Accord shifter; Hush22 cable-to-hydro conversion

Suspension Function+Form Type I coilovers; Energy Suspension and Prothane bushings; Skunk2 upper control arms front and rear; custom rear tower bar, front/rear body drop; Blox roll center adjusters

Resistance Mini Cooper 11-inch rotors front, Integra 10.3-inch rear; 2005-06 CRV calipers front; 1999-07 MR2 rear; custom hard lines; brake booster delete; Wilwood 7/8

Outside rear window removed for ventilation of the engine compartment; side scoop air intake

Cabin 1st-generation MR2 rear console; ITR shift knob; OEM 1990-91 Si seats

Thank you to my brother for buying me this stock CRX back in high school. And thank you to my wife for buying it back after I sold it in 2009 when I botched a simple D16z6 swap.

Click Image image to view product

Follow Davids work on his instagram: @david_builds_stuff