Air Suspension Best Practices

When it comes to upgrading your vehicle’s suspension, Type 5 air suspension systems are gaining popularity for their versatility and adjustable features. However, a successful installation requires careful consideration of potential challenges to ensure a smooth ride. Here are Air Suspension Best Practices to keep in mind when installing Type 5 air suspension:

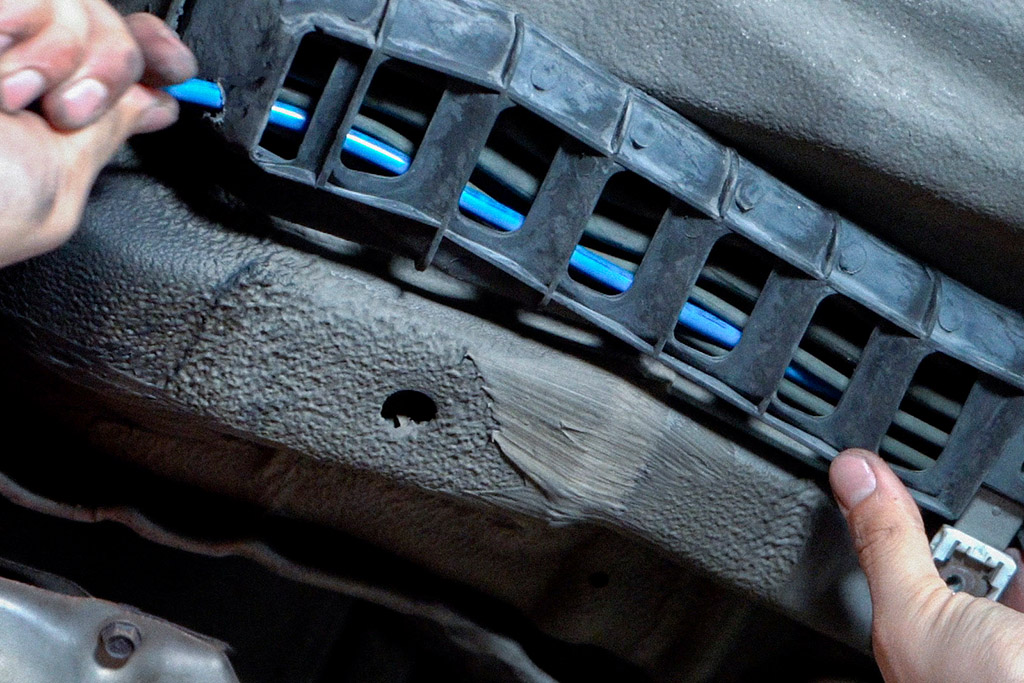

1. Check for Air Bag Rubbing:

One of the common post-installation issues with air bag suspension is rubbing. Pay special attention to the front upper control arm and the rear bag against the car body. Ensure that there is sufficient clearance during the entire range of motion. This precaution is crucial to prevent unnecessary wear and tear on the air bags, ensuring their longevity.

2. Upgrade Upper Control Arms if Necessary:

Not all vehicles are created equal, and some may need additional modifications for optimal performance. In cases where rubbing is persistent, consider upgrading the upper control arms to a tubular design. Tubular control arms offer more space, minimizing the risk of contact between the air bag and other components. This upgrade enhances the overall performance of the Type 5 air suspension system.

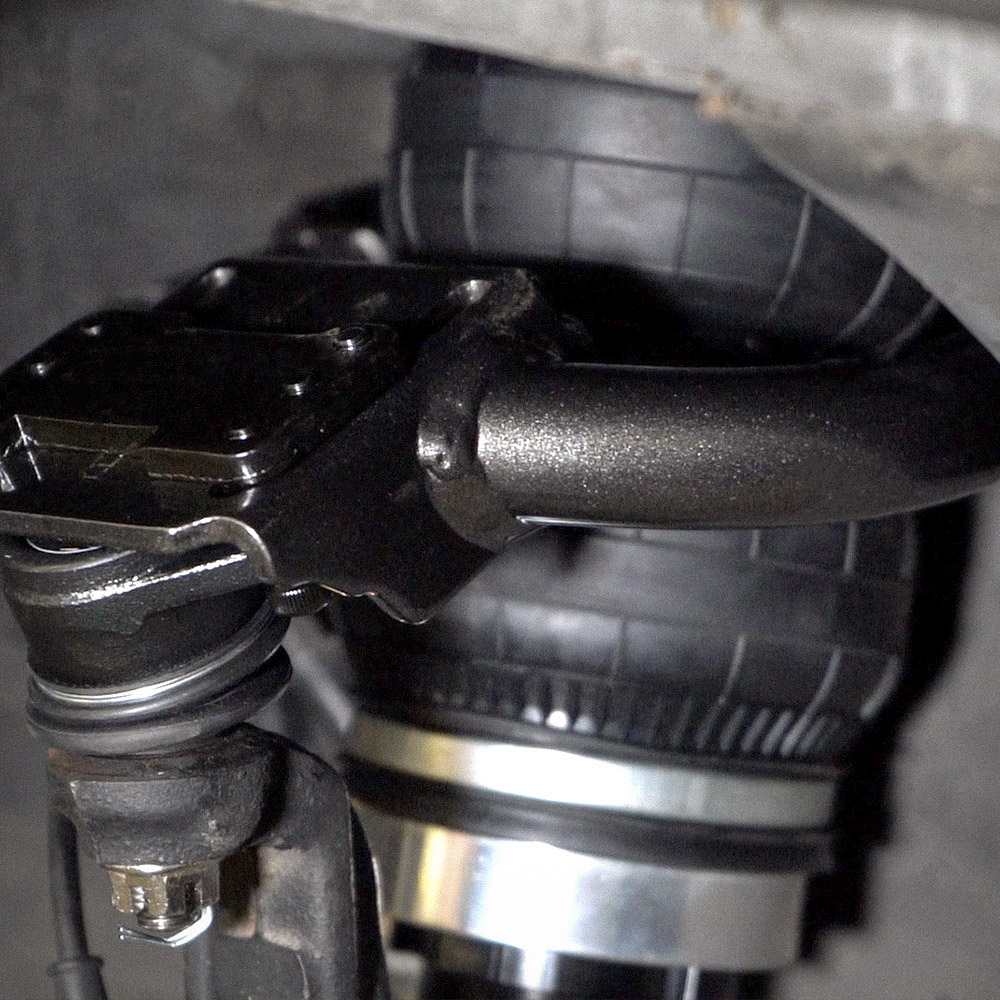

3. Check Air Line Orientation:

Ensure that air lines are not kinked or subjected to hard 90-degree turns during installation, as this may lead to cracks in the air lines over time. Make sure to turn your steering wheel from side to side while having a friend supervise to ensure that the tires do not rub against the air lines. This proactive approach helps avoid potential damage to the air lines and maintains the integrity of the entire system.

4. Regular Maintenance is a Must:

After a successful installation, commit to regular maintenance checks. Ensure that all components are in good condition, especially the air bags and associated parts. Regular inspections help catch potential issues early, preventing costly repairs and preserving the performance of your Type 5 air suspension system.

In conclusion, a successful Type 5 air suspension installation involves careful consideration of potential challenges and a commitment to regular maintenance. By addressing rubbing issues, verifying compatibility, checking air line orientation, and investing in professional installation, you can enjoy a smooth and reliable ride with your upgraded suspension system.

5. Drain Air Lines Every 6 Months:

To ensure optimal performance and longevity of your Type 5 air suspension, it’s crucial to drain the air lines regularly. Aim to do this every six months and consider more frequent drainage in colder climates prone to snow. This practice helps prevent moisture buildup, reducing the risk of freezing and potential damage to the system during colder months.